Andon lights and andon boards are famously utilized by Amazon. They’re a helpful measure for quality control, reducing downtime, and assembly line safety.

In this article, we’ll discuss the purpose and benefits of an Andon system, how Amazon is using them, and how to decide if your manufacturing plant should implement them as well.

What is an Andon System?

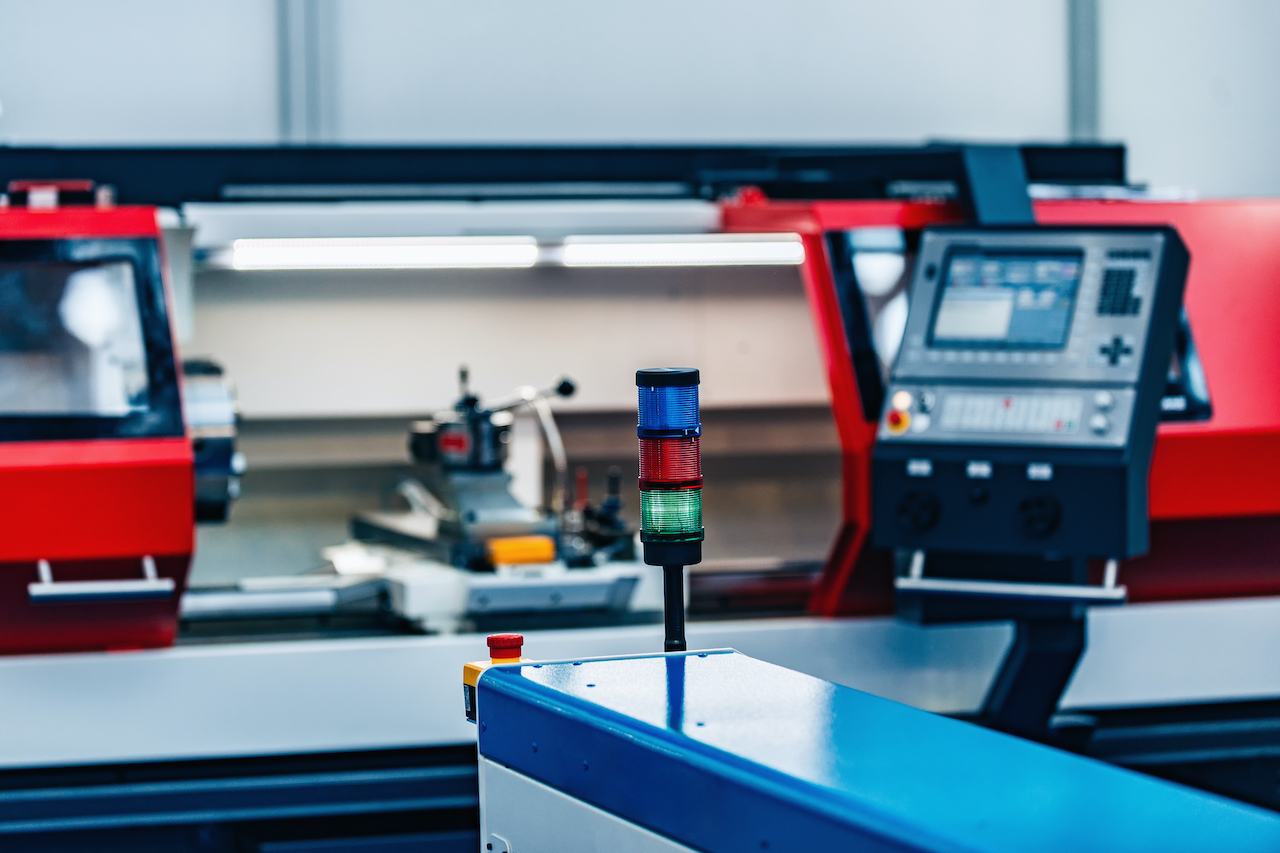

Throughout Amazon and other companies’ factories and warehouses, Andons exist to notify workers and supervisors when a process isn’t working or downtime is an issue.

A worker may notice that the machine he or she is using is not working and notify the appropriate personnel using the Andon system. This sends immediate communication and escalates the message to ensure a timely response to any issue.

An Andon board, on the other hand, notifies supervisors and managers of major issues with an assembly line. It keeps all employees up to date on the status of any problems and when they’re expected to be fixed.

Both of these processes are meant to improve and maintain a workplace and its products to a high standard.

Why Does Amazon Use an Andon System?

Consumers have a certain standard and expectation for any product they purchase. Andon systems help Amazon maintain these high standards.

Andon systems give workers and supervisors a chance to reduce wasted time and monitor each other’s progress and performance. Amazon’s massive workloads of packing and shipping products requires as little waste as possible, and Andons help accomplish this. Secure packing materials, processes, and quality checks are all part of Amazon’s processes.

Andon alerts can indicate a variety of issues on the production floor in real-time, meaning time isn’t wasted on fixing issues such as:

- Possible defects in units within Amazon’s inventory.

- A shipping address and RA number are needed so all on-hand inventory can be returned.

- Products in the warehouse need to be tested, and the reports sent to appropriate departments.

- User manuals or other related documents need to be provided for customer troubleshooting.

- Any recent updates made to the products need to be reported.

Using data from Andon systems, Amazon can fix issues on the spot and improve their processes to increase productivity. This industry leader relies on Andon technology as a main source of quality control so all their products are accounted for.

Should Your Manufacturing Firm Be Using Andons?

In general, Andons are a great fit for your business if you’re interested in reducing downtime and want to continuously improve and maintain your product and company standards.

The Benefits of Andons

- They help maintain and improve quality and standards within your business and workplace.

- They empower employees to proactively identify issues and receive a rapid response

- Anyone on the manufacturing floor can use the Andon system. This makes it the easiest way for consistent communication between your whole warehouse.

It’s important to make sure employees fully understand why Andons are valuable and how to use them. They need to be on board and willing to work towards making Andons a central part of your processes.

Andons can be a powerful tool for maintaining standards and improving your business and workplace as a whole. If you’d like to learn more about VersaCall’s Andon systems, check out this article.