Production & Process Monitoring System

Build to Order Mattress Manufacturing

Customer Issues

- Overall Production Status Visibility

- Visibility on the Time of Completion of the Daily Order Production Schedule.

- Measurement of the Individual Cells’ Performance Within the Production Steps

- Need for Immediate Communications to Address Production Issues.

- Identify Production Quality Issues by Reasons and the Time It Takes to Resolve Each Issue

- Visibility on the Performance Status of Mattress Production Steps – Inner Panel, Foundation Build etc.

Production Environment

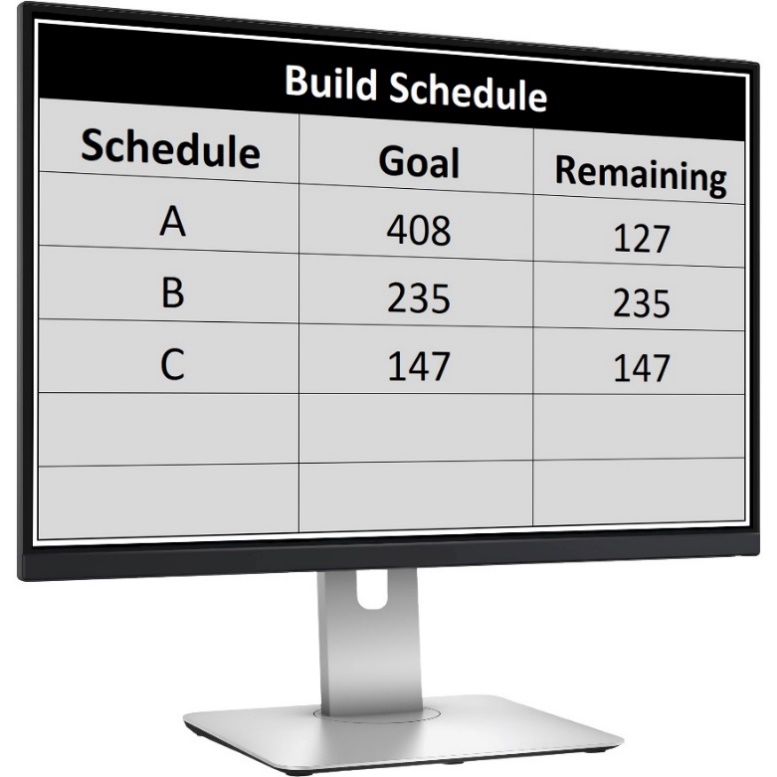

The production environment must support the build to order process. This results in daily changes to the mix of products required to be manufactured. This dynamic production schedule is further complicated by requirements to produce products in the order that they will be loaded into the truck trailers.

To achieve this, the daily production schedule is broken into 3 separate production build phases. The 1st build fills the front section of the trailer which is unloaded last; the 2nd build fills the middle portion of the trailer and the 3rd build completes the last section of the trailer. This production environment is further complicated by having to load multiple truck trailers each day.

The mattress production process is comprised of multiple independent work flows – Quilting Sewing (pillow top manufacture), Inner Panel, Border Sewing, Foundation Build; Mattress Build; Quality Assurance; Mattress Load. All of these independent work flows must be coordinated to meet a changing daily production schedule of producing quality products loaded in the trailers to be transported to the distribution centers each day.

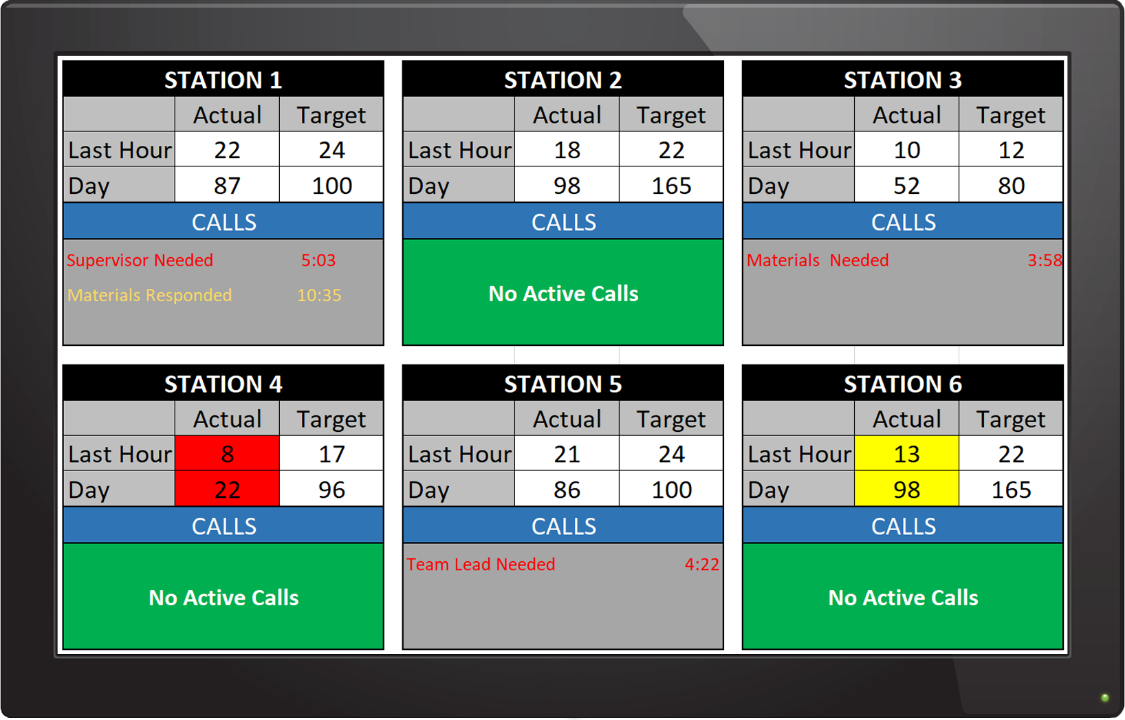

Visual Status – Total Plant By Work Area

The VersaCall System solution provides complete production status visibility of the entire production process. Input Modules capture production performance at each step of production. Dashboards provide real time visual status including hour by hour output at individual production steps, the production areas, total production process and the status of the production versus the daily planned schedule.

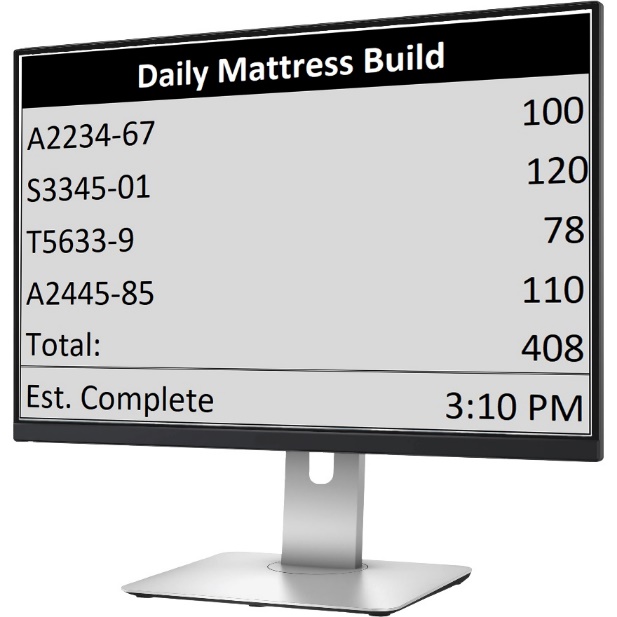

Daily Production Schedule Visibility

Complete production schedule performance visibility includes the time remaining for the remaining orders, and the estimated time for completion of the daily orders.

Overall Daily Production Status – Real Time

Visibility of the Daily Build Schedule Performance. Actual output of the production floor performance vs. the goal for the day.

Historical data is retained by the system providing complete visibility on the end items produced.

Output Performance to Target

The VersaCall System provides real time performance visibility by cell. Current actual cell output information that is compared against the daily goal. This information is able to be displayed anywhere in the plant including on mobile devices.

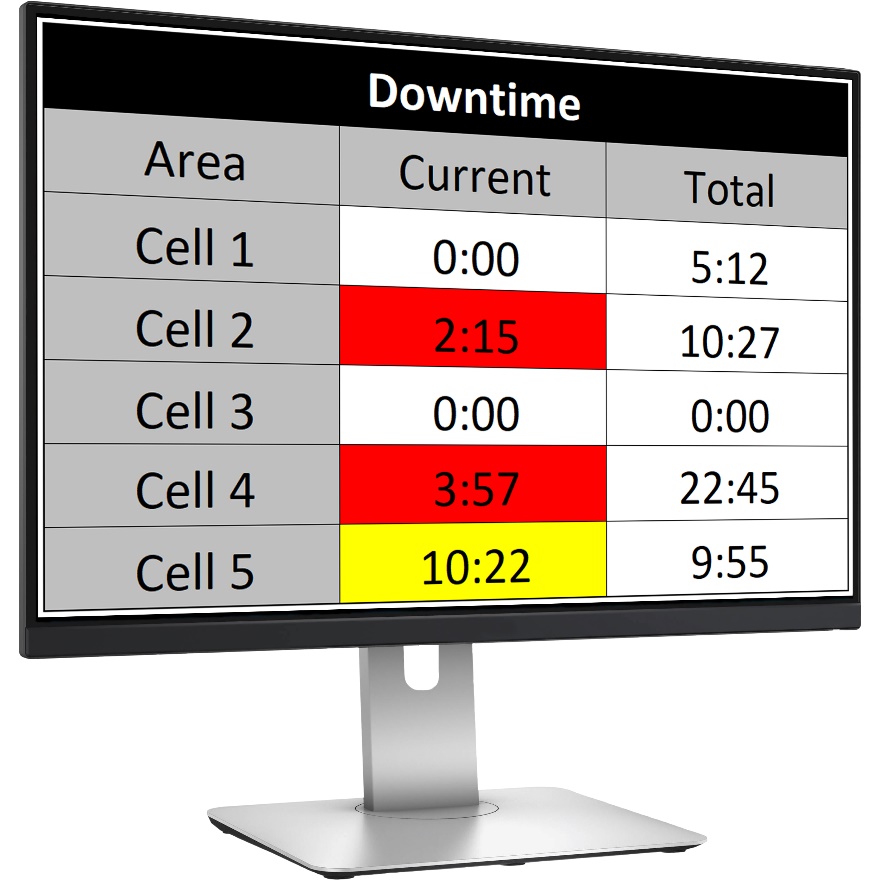

Downtime Visibility – Real Time

The system profiles downtime information by cell, and rolled up by production steps. Information is displayed for both the current downtime issues as well as the accumulative downtime for the shift.

Analytics

Clear, Concise, Actionable Visuals.