Production Monitoring System

Medical Device Manufacturing

Customer Issues

- Need to Reduce Production Downtime due to Material, Engineering and Work Instructions Issues.

- Need to Identify Root Causes of Production Issues.

- Visibility to Insure that the Corrections Implemented have Eliminated the Issue.

- Need to Significantly Reduce Response Time of Support Personnel Especially in the Clean Rooms.

- Identify Production Quality Issues by Reasons and the Time It Takes to Resolve Each Issue

- Need for a Centralized Production Management System – Unification of Data Generation, Reports and Support Methodology

Production Environment

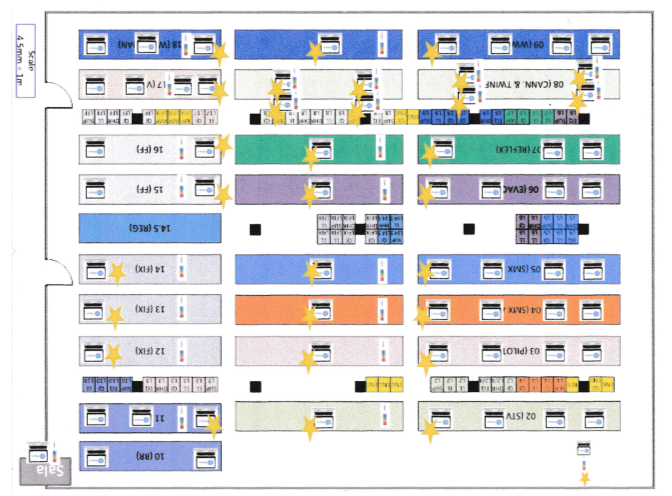

The production environment for this medical device manufacturer is a multi-station manual assembly operation in a clean room. The completed products go through a quality review in the clean room and finished units are forwarded to a multi-step assembly operation which is outside the clean room.

The products move through multiple work flow assembly steps. Below is the layout of the clean room production floor. This results in a completed product that is forwarded for testing and packaging for shipment.

There is a similar manual stations for work flows for stations for product quality review and packaging in the work area outside of the clean room.

VersaCall Solution

VersaCall System solution provides complete production status visibility of the entire production process from the clean room production to packaging. Wireless input modules strategically located throughout the operation capture all production performance information, assembly time, operator efficiency, downtime occurrences by reason code and location and safety incidents. They support immediate communications of issues, as well as supporting instant line stoppages for quality or other production issues.

Visual Status – For Individual Lines

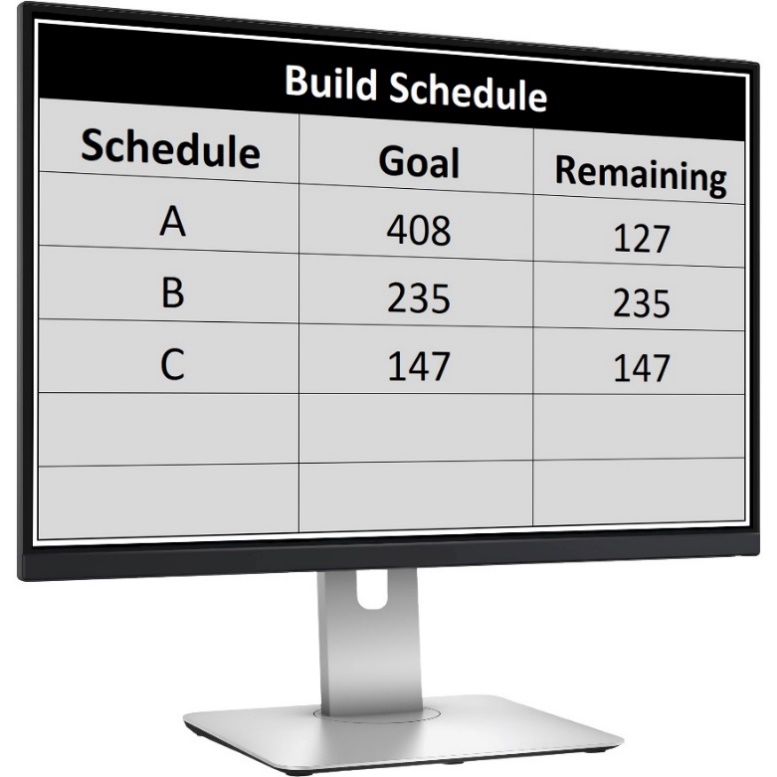

The VersaCall system provides real time performance visibility by individual cell within the line and rolled up by production step.

All downtime occurrences are automatically captured for each incident with reason codes.

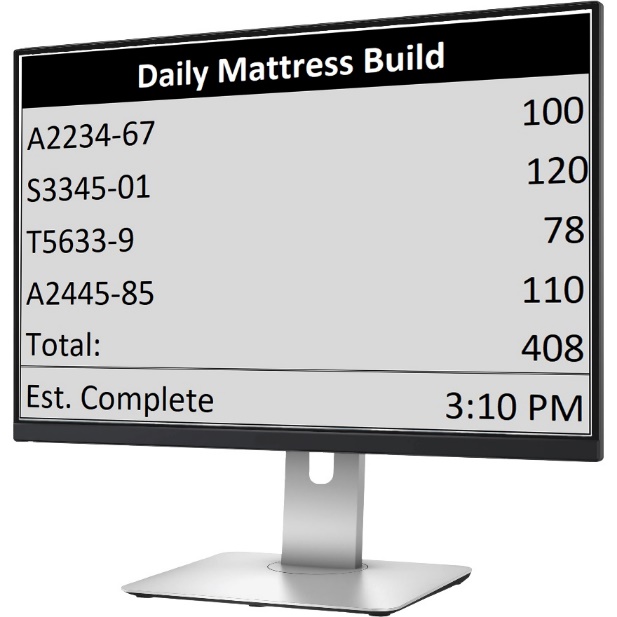

Automated Measurement Of Individual Production Work Order Order Performance

Product traceability information is captured for individual part numbers and work orders. This includes time estimations for planning.

Immediate Communication Of Issues

Production floor issues are immediately communicated to the appropriate individuals. Response time is captured for each incident. All of this information including root causes are automatically record in a database for reporting

All production disruptions are minimized with the VersaCall System.

Analytics

VersaCall provides daily reports by Line with the following metrics: Productivity ● Downtime Scrap ● Yield

The VersaCall System provides the full visibility of production efficiency in order to optimize the processes.

Results After System Implementation

VersaCall System provides a Centralized Production Management System for all areas of the production floor in the clean room and the assembly and pack out lines.

Root causes of production are automatically captured and logged into the database. Corrective actions are being tracked to ensure that the root causes have been eliminated.

Operations realize a significant reduction in downtime with the immediate communication of production floor issues.

Response time to issues especially in the clean room have been reduced by more than 50% .