Production Tracking & Production Monitoring System

Moving Assembly Line

Customer Issues

- Need Tools to Address Production Inefficiencies Due to Line Balance Issues

- Improve First Time Pass for Vehicle Production

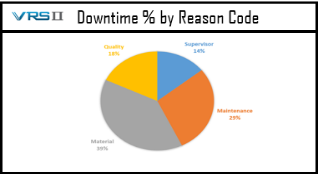

- Reduce Line Downtime for Quality Issues

- Need to Minimize All Production Issues with Immediate Communications

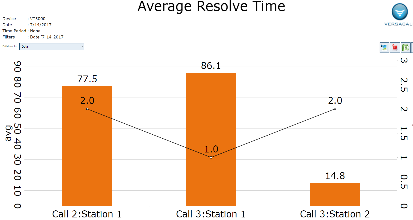

- Identify the Why for Vehicle Quality Issues & the Time it Takes to Correct Each Issue.

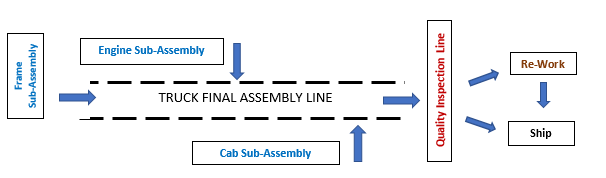

Production Environment

This is a complex manufacturing operation which coordinates and links three subassembly lines with a final assembly line, quality inspection line and a rework operation. The completed units pass through a multi-station quality inspection operation. There is also a unit rework operation. To add to the complexity, for the sub-assembly lines there is minimal completed units to be a buffer between the subassembly line and the final assembly line. Below is an overview of the moving assembly line production environment.

VersaCall Solution

VersaCall System solution provides complete production status visibility of the entire production process from sub-assembly production through to shipment. Wireless input modules strategically located throughout the operation capture all production performance information, talk time, downtime occurrences by reason code and location, and safety incidents. They immediately communicate production issues as well as supporting instant line stoppages for quality issues.

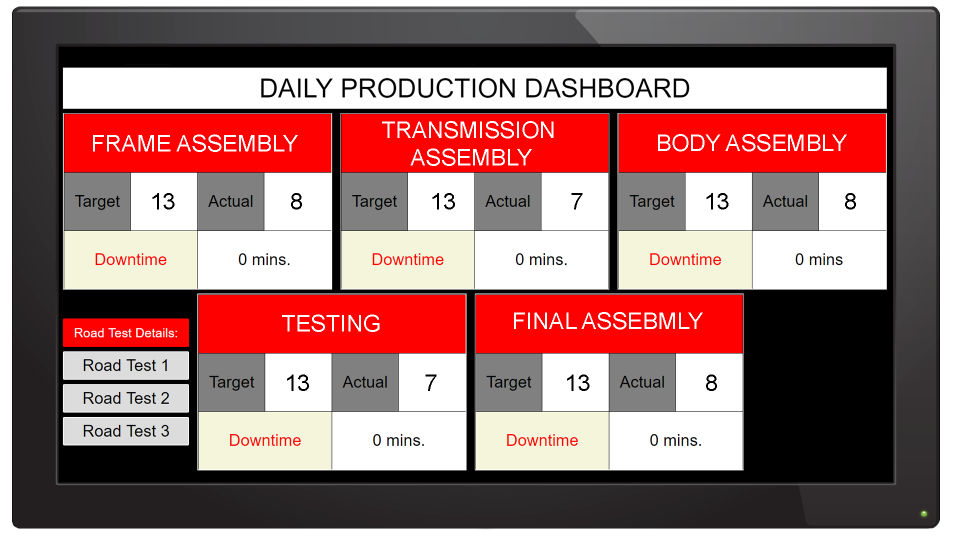

Visual Status – Total Plant By Work Area

Individual Station Production Visibility

Dashboards provide real time visual status for individual production steps

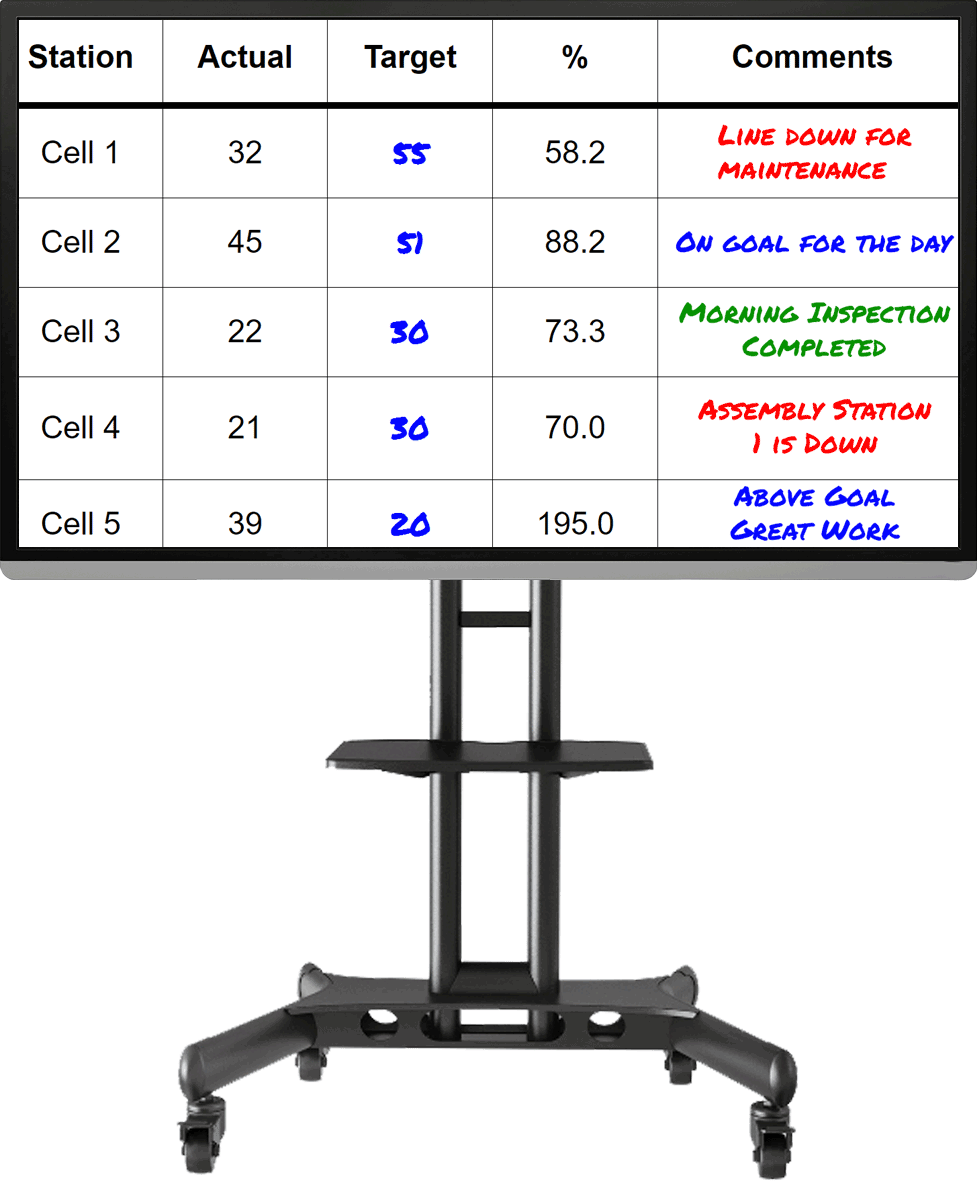

Daily Production Status Visibility

Production status visibility includes units on quality hold, completed units, remaining units to build, and the estimated time to complete daily orders schedule vs the original planned time.

Product production traceability information is captured for individual product serial numbers, product family and order types. This includes time to produce by individual production steps and total time to produce by product family.

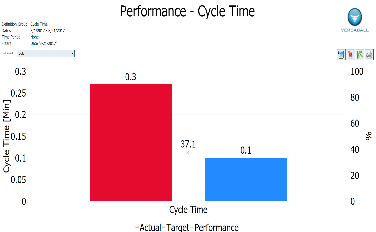

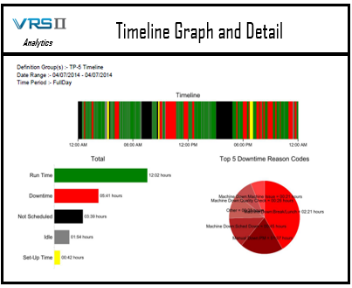

Analytics

Historical data is retained by the system providing complete visibility of past production builds.

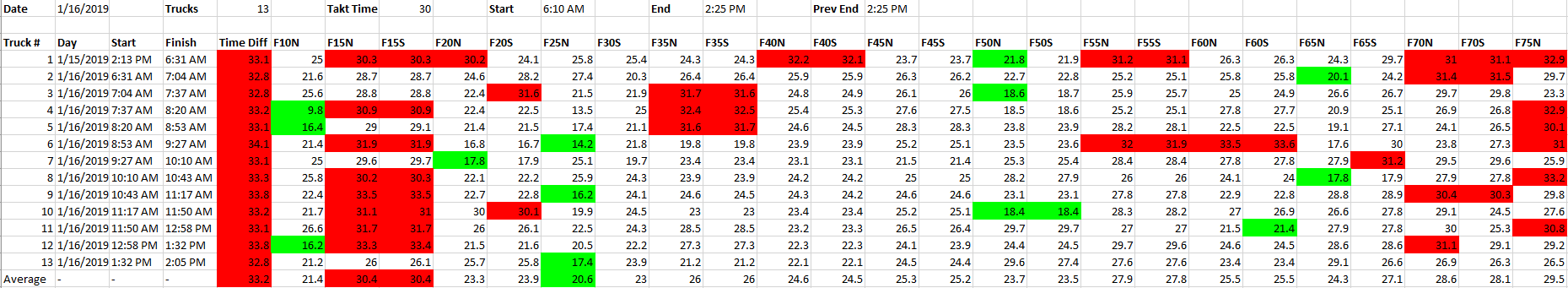

Line Balance Visibility

Achieving line balance of the subassembly production lines for the primary assembly line is critical for achieving overall production efficiencies.

VersaCall provides the tools for line balancing visibility in order to address line balance issues before they impact the primary production line.

Results After System Implementation

First Time Pass > 90% (Originally 30%)

Quality Issues Are Addressed Under 2 minutes – Average Clear Time 5 Minutes

Line Balance Issues Were Eliminated